- Home

- Learn Linux

- Learn Electronics

- Raspberry Pi

- Programming

- Projects

- LPI certification

- News & Reviews

Electronics does not have to be an expensive hobby depending upon how complex circuits are created and how "professional" the circuit is to be created. At the cheap end it could be a basic electronic circuit created using wirewrap, at the other extreme an individual printed circuit board could be created using photo-developing and etching, testing using a dedicated oscilloscope.

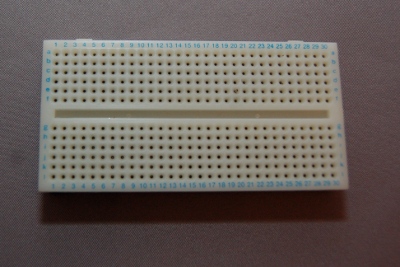

Solderless breadboards provide a way of creating a circuit without having to use solder or damage the components. They are particularly useful for trying out a part of a circuit before committing to solder or specialist PCB manufacture. They are rarely used for a final design due to their size and lack of permenant fixing for the components.

Solderless breadboards provide a way of creating a circuit without having to use solder or damage the components. They are particularly useful for trying out a part of a circuit before committing to solder or specialist PCB manufacture. They are rarely used for a final design due to their size and lack of permenant fixing for the components.

I have also created boards which allow breadboards to be mounted along with 4mm banana plugs and an Arduino / Raspberry Pi. The video below shows how this is designed in FreeCAD.

A soldering iron is used to make a permanent electrical connection between components and leads / wires. They are available as a basic fixed temperature soldering iron costing only a few pounds, to temperature controlled soldering stations costing £70 or more.

Soldering irons are avaialable at different power ratings. The higher the power rating the better the soldering iron is at maintaining the correct temperature and how quickly it heats up. It does not neccessarily mean that it will have a different operating temperature which is normally around 400°C (this temperature is required for lead-free solder which has a much higher melting temperature than older lead based solder). Temperature controlled soldering irons are available and can be useful for soldering delicate components. Whatever temperature is used care should be taken to reduce the amount of time that the iron is in contact with sensitive components or a shunt be used to dissipate the heat.

It can also be useful to choose a soldering iron with interchangable tips.

A soldering iron stand and sponge is also very useful to avoid burning your work surface. These are often included with the soldering iron, or are available for only a few pounds.

It can be very difficult to hold a component in place and solder it at the same time. A helping hands tool can be a great help in holding the board and/or component in place when soldering.

A different kind, sometimes called a third hand, has crocodile clips mounted on flexible pipes. The image below shows these in use soldering an LED.

When soldering circuits at some point you are going to need to remove a component. This may be due to inserting a circuit in the wrong place / wrong way around, it could be due to a failed component or it may be that you change the design. If you are unluckly you may even do all three on the same project!

A desoldering tool provides an instantaneous suction which will remove molten solder from the circuit board and component lead. These are available as a mechanical only device or with a built in heating element to melt the solder and suck the solder up in one tool.

Whilst soldering sensitive components it is possible to overheat and damage active components such as transistors. To avoid this soldering of active components is best left until after non-active components is complete and to keep the soldering time down as short as possible. A heat shunt can be used to further protect the component. It is placed on the lead between the component and the soldering point and will absorb some of the heat preventing it damaging the component.

Heat shunts are normally used for devices with long leads only. An alternative technique for integrated circuits (ICs) is to use an IC mounting socket instead of soldering direct to the IC.

A multimeter is very useful for measuring voltages, current and resistance within a circuit. Many also include additional functions including continuity tester, diode tester, capacitance measurer somtimes transistor testers.

Oscilloscopes and logic analysers are useful for visualising voltage changes within a circuit to see if a circuit is behaving correctly. Unfortunately these can be very expensive. There are some cheaper options which connect to a USB port of the computer. There is also an alternative which is to use the Arduino, your PC and a little bit of circuitry to provide a basic working oscilloscope / logic analyser.

Standard metal working tools can be used for most metal or plastic cases. There are some specialist tools that can useful in certain instances.

A rotary tool can be particularly useful for work on PCBs and stripboard. These are available in a kit with a number of different cutting / filing bits.

When using a metal case where possible it is usually easier to mount circular components to the case as these can easily be drilled or cut using a drill saw. Sometimes it is neccessary to square or rectangular components which is where the nibbler comes in by nibbling away at the metal. It will normally be neccessary to do quite a bit of filing after cutting the case, but this is often easier than drilling or trying to use a hacksaw blade.

Please view the copyright information regarding use of the circuits.